7 Ways Diesel Trailers Can Revolutionise Your Construction Site

The success of any major construction, civil works, or resource extraction project hinges on one crucial factor: keeping the machinery running. Nothing slows down progress faster than a fleet of dozers, excavators, and graders sitting idle, waiting for fuel. In the demanding environment of a busy site, relying solely on fixed fuel bowsers or slow, cumbersome fuel trucks is often inefficient.

This is where smart logistics and specialised equipment come into play. Investing in high-quality, reliable diesel fuel trailers can fundamentally change how you manage resources, driving down operational costs and dramatically increasing uptime. These aren’t just big metal tanks on wheels; they are meticulously engineered mobile solutions designed to meet stringent industry standards and handle the toughest conditions our terrain can throw at them.

More than just a fuel carrier: The modern diesel trailer

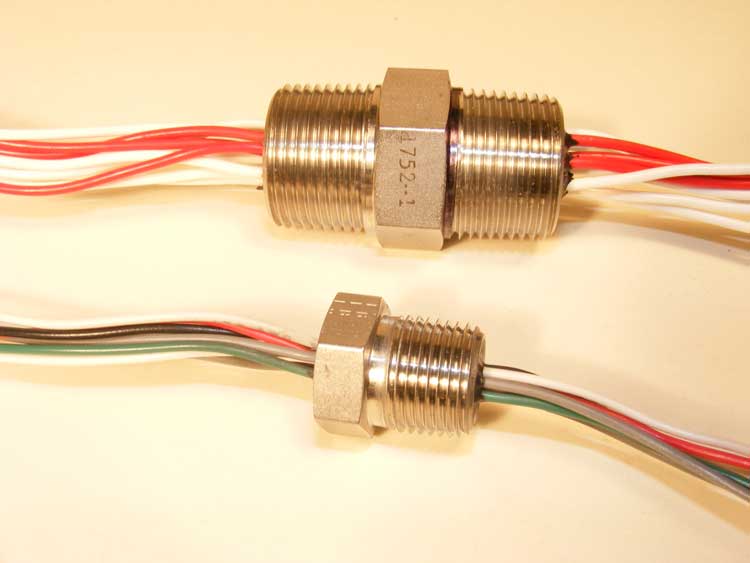

When you picture a fuel trailer, you might envision a basic farm tank. However, modern, purpose-built diesel trailers used across construction and mining sectors are highly sophisticated pieces of gear. They are designed for safety, precision, and durability. They often include features like integrated pumping systems, fire suppression, advanced metering, and robust chassis construction that can handle rough access roads and dusty site conditions.

The ability to move fuel directly to the point of consumption is a game-changer. Imagine a remote civil works site kilometres away from the nearest depot, or a large subdivision development where earthmoving gear is constantly relocating. Having readily available, secure fuel storage that can be easily towed by a ute or light truck provides unparalleled flexibility. But how exactly do these specialised units deliver on that promise? Let’s break down the seven core benefits.

7 Ways diesel trailers boost site efficiency

Efficiency in construction isn’t just about speed; it’s about the optimal use of resources – time, labour, and fuel. By integrating professional-grade mobile refuelling solutions, project managers can minimise bottlenecks and improve overall productivity.

1. Minimise downtime and maximise output

Every minute a machine is stopped costs money. Waiting for a fuel delivery or driving heavy equipment back to a central depot for refuelling can easily chew up an hour or more of productive time per machine, per shift. By using a robust diesel trailer, you bring the fuel directly to the equipment, wherever it is working on site. This hot refuelling capability means large machinery downtime can be reduced to mere minutes, keeping your tradies active and the project moving.

2. Optimise fuel management and security

Fuel theft and inventory mismanagement are significant issues on large, sprawling sites. Modern diesel trailers are designed with security in mind. They feature lockable compartments, secure dispensing nozzles, and often integrate metering systems. This allows site managers to accurately track usage, minimise waste, and ensure that valuable resources are protected, helping to minimise operational losses. Detailed metering also assists greatly in cost allocation across different phases or contracts of a project.

3. Enhanced mobility and access

Construction sites are dynamic. What was accessible yesterday might be a muddy mess today, or the work front may have shifted kilometres away. Standard fuel trucks can struggle with tight corners, steep grades, or unstable ground. A well-designed diesel trailer, however, is built with high ground clearance, heavy-duty suspension, and often features a more compact footprint, allowing it to be towed easily into difficult-to-access areas where the heavy machinery is actually operating. This mobility is essential when dealing with remote infrastructure projects or large-scale earthworks.

4. Compliance and safety on site

Adhering to strict safety and environmental regulations is non-negotiable. Reputable suppliers engineer their fuel trailers to meet stringent local building codes and dangerous goods standards. Features such as bunded tanks (double-walled containment) are critical for preventing spills and protecting the environment. Furthermore, having clearly marked, compliant fuel transport equipment demonstrates a commitment to workplace health and safety (WHS), which is crucial for tendering and insurance purposes.

- Bunded construction prevents environmental contamination from leaks.

- Integrated fire extinguishers and safety signage ensure visibility and preparedness.

- Compliance with transport regulations for moving flammable liquids.

- Secure access points minimise the risk of tampering or accidents.

5. Versatility beyond just diesel

While the primary function is diesel transport, many of these trailers are designed with versatility in mind. They can be configured to carry multiple fluids, such as lubricants, hydraulic oil, or even water for dust suppression or cooling. This multi-purpose functionality means that one unit can serve several needs on site, further optimising logistics and reducing the number of separate pieces of support equipment required. This versatility is highly valued by contractors who service a wide variety of equipment, from graders to compact loaders.

6. Reduced labour costs and reliance on bowsers

By shifting the refuelling task from the equipment operator to a dedicated support vehicle driver, you free up expensive machinery and skilled operators to focus purely on production. Instead of having operators spend time travelling to and waiting at a fixed fuel centre, the mobile refuelling unit handles the task efficiently. This centralisation of fuelling operations streamlines workflow and reduces the overall labour hours wasted on logistical movements.

7. Longevity and durability in tough environments

The construction and resource sectors demand equipment that can withstand extreme heat, dust, vibration, and general wear and tear. High-quality diesel trailers are fabricated using robust materials, often featuring heavy-duty axles, reinforced drawbars, and protective coatings to resist corrosion. This focus on durability translates into a longer service life, lower maintenance requirements, and reliable performance year after year, offering a strong return on investment.

Choosing the right trailer for your operation

Selecting the appropriate diesel trailer depends entirely on the scale and nature of your work. Are you managing a small civil contract requiring only occasional refuelling, or are you overseeing a large-scale project where constant fuel flow is essential? Capacity, dispensing rate, and chassis design are all critical factors.

For operations that require constant, high-volume fluid management, such as large quarries or remote infrastructure developments, the trailer choice might need to align with your wider fleet of heavy-duty Mining service vehicles and equipment. Understanding the operational tempo of your site is key.

Key considerations for selection:

Tank capacity

Does the capacity meet your daily consumption needs without requiring multiple trips? Trailers range from small, portable units suitable for light earthworks to massive semi-trailer configurations designed for sustained operation in the resource sector.

Dispensing speed and accuracy

High-flow pumps are essential for quickly refuelling large machinery. Look for reliable pumps and accurate meters to ensure you are dispensing fuel efficiently and tracking usage precisely.

Towing requirements

Ensure the trailer’s weight (when full) is compatible with the towing capacity of your site vehicles (utes or light trucks). Compliance with road rules and local council regulations regarding towing heavy loads is paramount.

Ultimately, the right choice of equipment transforms a logistical challenge into a competitive advantage. By ensuring your construction site has access to reliable, secure, and mobile refuelling capabilities, you are protecting your investment and guaranteeing that your project meets its deadlines without unnecessary delays.

Frequently asked questions about diesel trailers

What is the difference between a diesel trailer and a standard fuel tank?

A standard fuel tank is typically stationary and used for bulk storage. A diesel trailer is specifically designed for transport and mobile dispensing. Quality diesel trailers feature robust, road-legal chassis, high-grade pumping systems, and safety features like protective bunding and secure lockable compartments, allowing them to legally and safely move fuel directly to equipment on site or between locations.

Are diesel trailers compliant with Australian safety standards?

Reputable manufacturers engineer their diesel trailers to comply with strict Australian Design Rules (ADRs) for road transport and local WHS regulations concerning the handling and storage of dangerous goods. It is essential to verify that any purchased or hired trailer meets these current standards, particularly regarding tank construction (e.g., bunding) and fire suppression requirements.

Can a standard ute tow a full diesel trailer?

It depends entirely on the capacity of the trailer and the towing limits of the ute. Even a mid-sized diesel trailer can weigh several tonnes when full, potentially exceeding the legal towing capacity of many standard utes. Always check the Gross Trailer Mass (GTM) of the fully laden trailer and compare it against the maximum towing capacity specified by the vehicle manufacturer and local road authority regulations.

How often do diesel trailers require servicing?

Like any piece of heavy-duty equipment, professional diesel trailers require regular maintenance to ensure safety and functionality. This typically includes routine checks of the tyres, brakes, lights, and suspension, as well as regular inspection and calibration of the pump, filter, and metering systems. Following the manufacturer’s recommended service programme is crucial, especially when operating in dusty or corrosive environments.

What features should I look for to ensure long-term durability?

Durability hinges on construction quality. Look for trailers built with heavy-duty steel, galvanised or protective coatings to prevent rust, and robust running gear (axles and suspension) capable of handling rough terrain. High-quality components for the pump and hose reel, along with a fully bunded tank design, will also contribute significantly to the unit’s longevity and reliability.